Precision CNC Grooving Service

CNC Grooving Service

CNC grooving like other forms of CNC machining, has had a wide impact in different industries. For many years, this unique technology has been a part of different CNC manufacturing methods. If operated correctly, CNC grooving can bring precision, cost-effectiveness, and versatility to the project.

Grooving is just a part of our ability. Our strengths also include CNC milling, boring, turning, etc. Please contact us for more insights on all types of CNC machining processes

Advantage of CNC Grooving

CNC grooving, which involves the use of Computer Numerical Control (CNC) machines to create grooves or channels in a workpiece, offers several advantages over manual or traditional grooving methods.

Precision and Accuracy

The CNC machine’s ability to follow programmed tool paths ensures consistent groove dimensions across multiple parts.

Improved Surface Finish

CNC grooving can produce high-quality, uniform surface finishes within the grooves, minimizing the need for additional finishing steps.

Increased Productivity

This integration allows for faster production times and reduced labor costs compared to manual or semi-automated grooving methods.

Versatility

The flexibility of CNC grooving enables efficient manufacturing of small-to-medium production volumes with design changes.

Consistent Quality

The automated nature of CNC grooving ensures consistent groove quality from part to part, reducing the risk of defects and improving overall product reliability.

Enhanced Design Flexibility

CNC grooving allows for the incorporation of complex groove geometries and patterns that would be challenging or impossible to achieve using traditional manual methods.

Type of CNC Grooving Tool

Several designs of grooving tools are available, but they are all usually cemented carbide or high-speed steel (HSS) types. Below is a brief coverage of these types of groove cutting tool:

Outer Diameter Grooving Tools

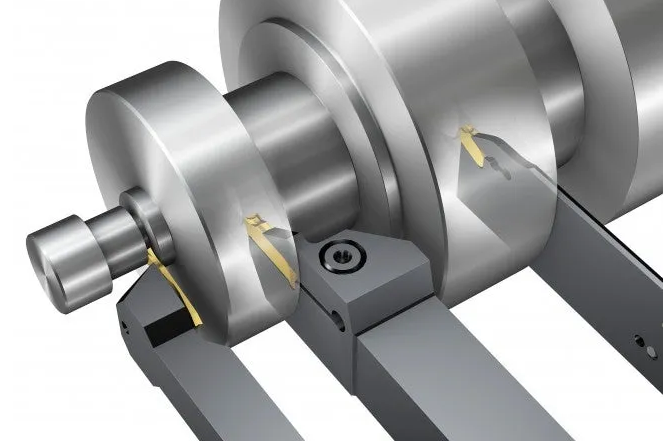

In an external groove, the idea is to create an external feature or even a gear that serves in different applications. The outer grooving tool can have different geometry and dimensions to achieve the groove parameters that the machinist desires.

Face Grooving Tool

If the groove aligns to the workpiece axis, we call it a face groove. The cutting tool that produces this type of groove is the face grooving tool. This tool comes in handy in creating grooves at a part’s face. The capability of this tool to reach seemingly unreachable parts of the workpiece is the biggest advantage.

Inner Diameter Grooving Tools

For creating a groove inside a pipe, tube, or any other hollow component, you need an outer diameter grooving tool. The resulting internal groove holds in place seals that enhance the functionality in a wide range of items.

CNC Grooving Process

Grooving operations encompass several stages, each playing a vital role in ensuring the successful production of accurate and consistent grooves.

Step1: Planning and Designing

Before the actual machining process begins, the groove’s specifications, including its size, depth, and location, are meticulously planned and designed. This design stage often employs CAD (Computer-Aided Design) software to generate an accurate model of the final product.

Step2: Setting Up the Machine

Once the design is finalized, the machine is set up for the grooving operation. This involves selecting the appropriate grooving tool based on the design requirements and installing it in the lathe or CNC machine. The workpiece is then mounted and correctly aligned to ensure precision during the operation.

Step3: Executing the Grooving Operation

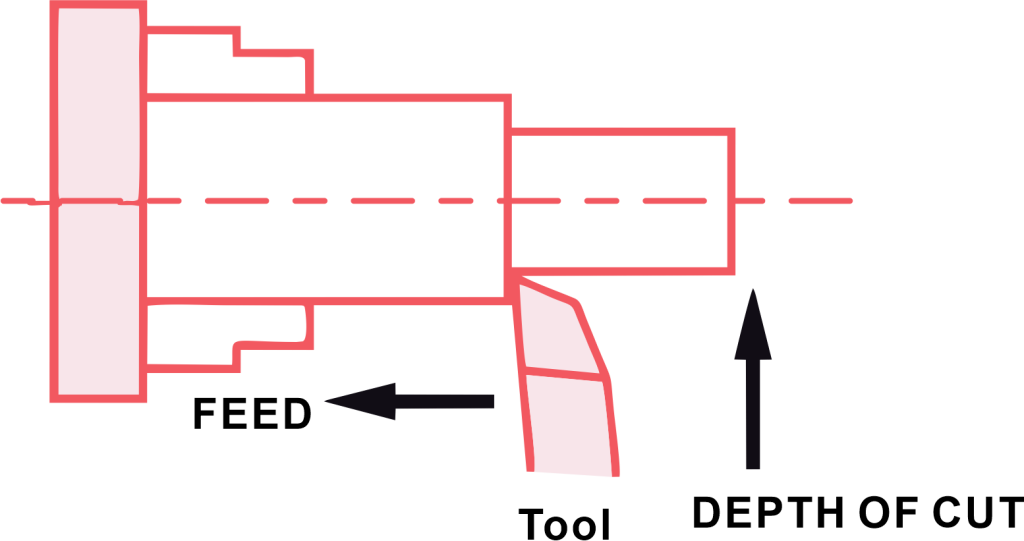

The grooving operation is then performed according to the planned process. In a manual lathe, the operator carefully controls the tool’s feed and depth of cut. In a CNC machine, the program controls these parameters, ensuring high precision and consistency.

Step4: Quality Inspection

After the grooving operation, the resulting workpiece is inspected for accuracy and quality. This may involve visual inspection, measurement with gauges, or even more advanced methods such as CMM (Coordinate Measuring Machine) inspection. If any discrepancies are found, adjustments are made in the machining process.

Types of Grooving Methods

Straight Turning

Also referred to as cylindrical turning, straight turning reduces the diameter of the workpiece to a specified measurement. The grooves in this case are open. Here, the operation involves a straight-turning tool.

Face Grooving

In this type of grooving method, the grooves align to the axial direction of the workpiece. A face grooving tool does this type of machining.

Contour Grooving

When you want to create specific geometries for the groove, you use the method called contour grooving. Contour grooves suit situations where the path is non-circular or non-linear. While there is more freedom in groove design in this case, the programming part can be challenging.

Internal Grooving

As mentioned above, internal grooving creates grooves in a hollow surface, for example, a pipe.

External Grooving

External grooving entails the production of grooves on the external surface of the material or workpiece. You can use this process to produce three types of external grooving:

- Single-cut Grooving – As the name suggests, this grooving variety entails a single cut on the outer surface of the workpiece.

- Multiple Grooving – The CNC machine creates several deep grooves on the outer diameter of the material.

- Ramping – In this type of grooving, the radial and axial movements are sequential during the machining process.

Considerations When Choosing A Grooving Tool

There are several factors to consider when choosing the best grooving tool. Here is an overview of some of them:

Types of Groove

Cutting tools are designed for different cutting operation and setups. There are specific grooving tools for particular types of grooves. A cutting tool for internal grooving may not work for external grooving.

Materials Property

Every grooving tool has qualities that suit properties of a particular material or set of materials. Types of materials that you can groove are plastic, metal, wood, and so on. The grooving tool should be compatible with the material.

Groove Geometry

Depth and width are the key geometries of a groove. Every grooving tool has design capacity to produce particular groove geometry. The cutting tool that you select for grooving should be capable of producing the desired depth and width of the groove.

Cutting Parameters

The machine parameters such as feed rate and rotation speed are equally important when choosing a grooving tool. Choose a tool that can operate optimally within the limits of the machine.

Machine Setup

The setup of the machine, particularly regarding the toolholder, is essential when choosing the perfect grooving tool. That’s because the safety and functionality of the cutting tool depends on how well it is secured to the CNC machine.

Conclusion of CNC Grooving

We have looked at the definition of CNC grooving and discussed several aspects of the process – types of grooves, types of grooving tools, choosing a grooving tool, and much more.

When it comes to groove machining, you may need the support of an experienced CNC machining company. That’s where we come in. We have modern CNC machines and expertise in different axes of CNC machines.

Grooving is only part of what we are capable of. Our forte also entails CNC milling, boring, turning, and others. Contact us for more insights into all types of CNC machining processes.